Performance & Excellence Starts Here

With State of the Art Technology and Products

PolyBilt Body Company builds the toughest, most durable tanks and bodies in the industry, with a limited lifetime warranty to back them up. Stringent engineering guidelines, highly skilled fabricators and unique production methods like the Bent Edge, the Pro Lock System and Extrusion Welding makes us confident in our products ability to live up to the Pro One Warranty.

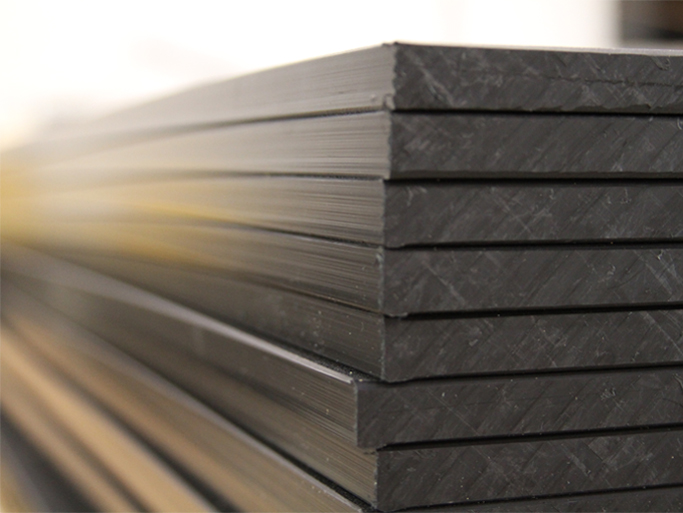

POLYPRENE®

Polyprene® is a specially formulated copolymer sheetstock material used in the construction of fire service products. The resin used in making Polyprene® is a combination of polyethylene and polypropylene polymers which results in stronger physical properties in either high or low temperature applications. Polyprene® will not rust, corrode, dent, crack, chip or peel. Polyprene® welds are impervious to microbial attack and meet FDA approval for food grade surfaces. Also, Polyprene® is lighter than steel, aluminum or fiberglass in the same application.

Lightweight

Lifetime Warranty

Recyclable

Dent Resistant

The Advantages of Polyprene®

Impact, Heat and Chemical

- Will not rust, corrode, crack, chip or peel

- Superb impact resistance due to unique combination of strength and flexibility.

- Eliminates shock transfer through the body in the event of high speed collision, Keeping damage to a minimum.

- Resistant to damage from high heat exposure

-

Polyprene material is welded at 707° F (375° C) with pressure and at a slow speed of 12" per minute.

- Vehicle paint will ignite and tires will melt before body is affected.

- PolyBilt" bodies are easy to clean after exposure to hazardous materials or when used in decontamination operations.

Practical and Financial

- Lighter weight than steel or aluminum truck bodies

- Integral tank design means larger compartments and more water.

- Lighter body so carries more equipment.

- Lower center of gravity, giving safer driving.

- Custom designed to meet your specific needs.

- Easily recycled at the end of its life.

- High impact resistance - less down time.

- Long operational life up to 40 years.

-

Low risk with a limited lifetime warranty.

- Low risk with proven technology and proven operation experience.

- Re-mountable for second life.

Maintenance

- Does not require special environment, extraction, etc.

- Does not require special personal protective equipment (PPE).

- Does not require specialist equipment.

- Does not require specialized knowledge.

- Easily adapted to carry changing equipment needs.

- Easily repaired - only requires 2 hours of training.

- Resists damage so fewer repairs.

- Zero maintenance for rust or corrosion. Does not crack, chip or peel.

Technology and Production

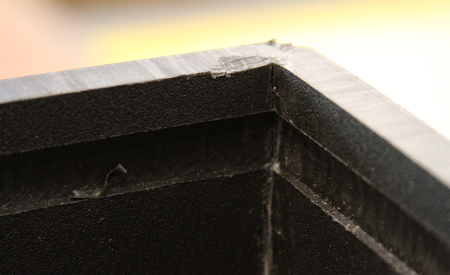

Bent EDge™

What is Bent Edge? It is a patented process, exclusive to PolyBilt, of heating and bending sheet stock to form a continuous, seamless corner void of any joints, therefore eliminating the chance for leaks in these areas. Simply put, there is no stronger way to build a poly fire truck tank than with Bent Edge.

Extrusion Welding

20' Precision Router

Pro Poly of America, Inc. uses a 20 foot precision router which enables us to run sheets of polyprene the neccesary lengths with as few seems as possible. This technology provides for a stronger, safer design that lessens the chance for any leaks that could result in system failure.